How To Use Push Fit Plumbing And Fittings

WHAT IS A PUSH-FIT FITTING?

If you’d like to find out more about push-fit fittings, take a look at our helpful guide.

CAN YOU USE PUSH-FIT WITH COPPER?

Plastic push-fit fittings, which were originally designed for use with plastic pipe systems, are also suitable for copper pipes (although they cannot be used with stainless steel or chrome-plated copper pipes.)

HOW TO INSTALL PUSH-FIT FITTINGS

Push-fit fittings have a quick and easy installation time, regardless of whether you're using plastic or copper. Follow the steps below along with images.

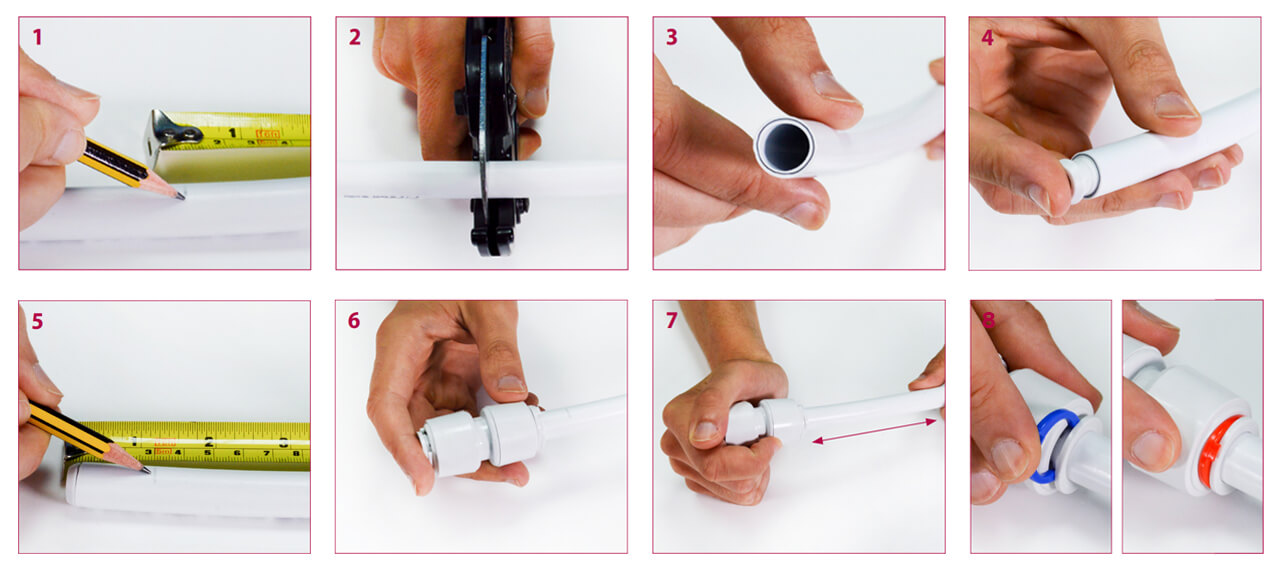

ON PLASTIC PIPES

- Measure and mark the required length. (Image 1)

- Cut the pipe using a pipe cutter – do not use a hacksaw, as cutting imperfections can greatly increase the risk of leaks. (Image 2 & 3)

- Fit the pipe insert into the pipe. (Image 4)

- Measure and mark the correct insertion depth on the pipe. (Image 5)

- Insert the pipe into the fitting, ensuring it passes through the O-ring until it reaches the stop point and correct insertion depth. (Image 6)

- Check that the assembly is secure by pulling the pipe away from the fitting. (Image 7)

- Use red or blue collet clips to help identify whether it’s a hot or cold circuit. (Image 8)

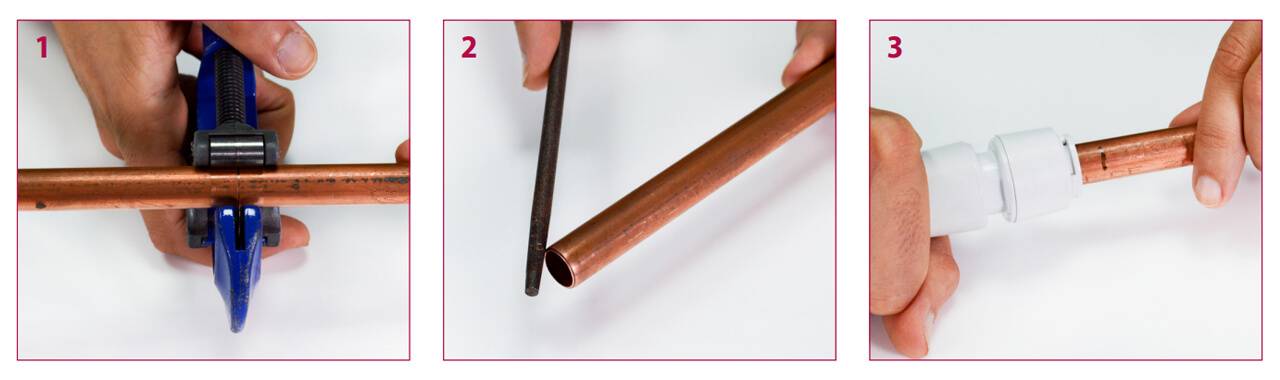

ON COPPER PIPES

- Firstly, measure and mark the required length. Ensure the pipe is cut with a rotational pipe cutter. Do not use a hacksaw.

- To reduce the risk of leaks, use a file to ensure you remove any burrs or swarf from the end of the pipe.

- Simply insert the fitting and ensure that the correct insertion depth is achieved.

BENEFITS OF PUSH-FIT FITTINGS

Push-fit fittings offer various advantages and may be utilised in a wide range of applications:

- Perhaps the most significant advantage is that they are quick and easy to connect. In an emergency, they can be used to swiftly cap or repair a pipe.

- They are an excellent choice to join pipes that create a watertight seal without the need for solder, clamps, unions, or adhesive.

- When employing push-fit fittings, pipes do not need to be completely dry. In contrast, CPVC and PVC must be bone-dry before solvent gluing, and copper pipes must be bone-dry before torch soldering.

- They are available in a variety of materials for a variety of purposes; almost every form of pipe has a corresponding push-fit fitting.

- They may be readily removed and repositioned as needed. If the connection is only intended to be temporary, the fitting can be used and quickly withdrawn from the pipe.